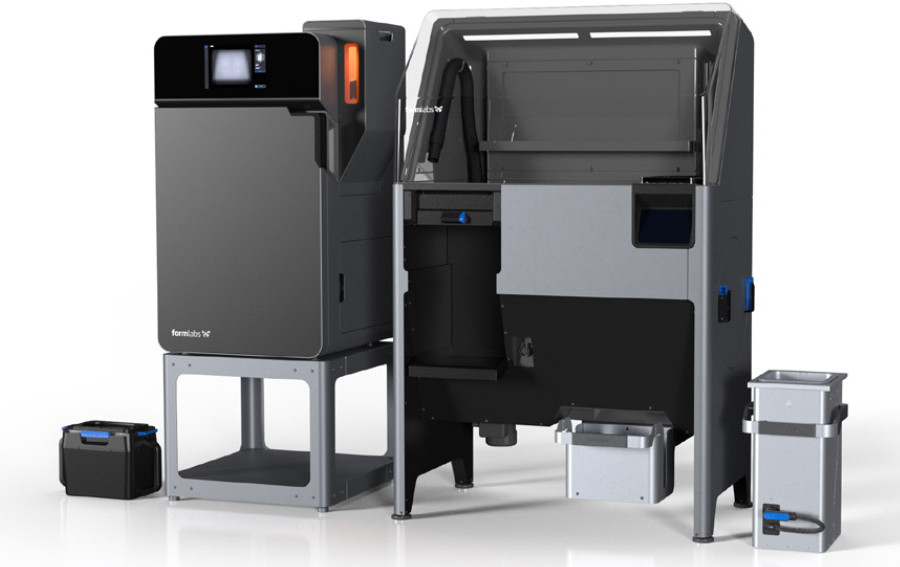

| Formlabs Fuse 1 (10W) Specs |

Build Volume (LxWxH) |

Laser Spot Size |

Layer Height |

Tolerance (Minimum Gap Reccomended) |

|---|---|---|---|---|

|

165x165x300mm | 200 μm | 0.11mm | ± 0.1mm |

We exclusively use Formlabs Nylon 12 power in our SLS machine. The technical data sheet (TDS) for this material can be found here.

¶ About Selective Laser Sintering (SLS)

The SLS process uses a powerful laser to sinter a tightly packed layer of fine powder together. After a layer of powder has been sintered together, the machine will lower the build plate slightly, and roll out a fresh layer of powder on top. The laser then sinters the next layer, and continues building up layers until the part is complete. After the process is complete, the sintered part is encased in a "cake" of unsintered powder, which is then brushed away, revealing the final part. Depending on type of machine, and strength of the laser, some SLS machines can even sinter full metal parts. Our machine's laser isn't strong enough to create metal parts, but it uses Nylon 12 powder to create very strong and robust parts.

Advantages:

- SLS printing requires no supports, due to the fact that overhangs will always be supported by previous layers of unsintered powder.

- While the FDM process requires lots of delicate tuning to achieve successful prints at 100% infill density, SLS printing creates parts that are inherently "solid." While the parts are solid, they are also porous, due to the nature of the sintering process.

- Up to 70% of the unsintered powder used during a print can be recycled for future prints.

Disadvantages:

- SLS printed parts are inherently porous, which may be an advantage or disadvantage depending on your application.

- When printing with SLS, any sealed voids in your part (i.e. a sealed, hollow sphere,) will be packed full of powder. Because of the way the process works, there is no way to print parts with hollow voids, and it's not possible to remove the unsintered powder inside without drilling holes to excavate the cavity.

- Thin parts may or may not succeed, depending on the cross-sectional geometry.

- Wire-frame models, hollow parts, and other geometries that leave large volumes of unsintered powder (lower than 30% packing density) can become much more expensive than usual, as only 70% of the powder can be recycled.

¶ Usage Instructions

¶ Slicing

To prepare your 3D models for use in our machines, please follow the instructions for the installation, setup, and usage of PreForm on the following page: PreForm

Slicing Shortcuts

- One Click Print (P): Automatically orients and packs your models. Be careful to check that models aren't overlapping.

- Size (S): Scales objects in x-, y-, and z-direction or the model as a whole.

- Orientation (O): Orients and rotates models by face, axes, or bounding box.

- Layout (L): Packs multiple models and modifies current models.

¶ Post Processing

Required PPE

- Latex or Nitrile Gloves

- Standard KN95 dust mask

![]()

![]()

Once the print has concluded, extract the tray from the machine, and place it in the Fuse Sift machine. From here, you can raise the "cake" containing your part (and any unsintered powder) to the level of the table. Turn on the sifter, and gently slide the cake over to the cleaning area of the tabletop. Next, begin excavating the unsintered powder to find your desired part(s) within the cake. Use the provided brushes and dental picks inside the hood to clean as much dust off of your part as possible. Please ensure that you leave the tools inside the hood for other users.

Optional additional processing:

Media blaster or sand blaster